WORLDWIDE

3D Printing

The Crucial Role of Humidity Control in 3D Printing: Dr. Storage's Solution for Optimal Results

3D printing has revolutionized various industries, from aerospace to healthcare, by enabling the creation of complex and customized parts with unmatched precision. However, there's a hidden factor that can significantly impact the quality and reliability of 3D printing—humidity. In this blog post, we will delve into why humidity control is essential in 3D printing and why the Dr. Storage system stands out as the ultimate solution for achieving exceptional results.

The Impact of Humidity on 3D Printing:

01

Material Sensitivity

- 3D printing materials, such as filaments and resins, are highly sensitive to humidity.

- Excessive moisture absorption can lead to material degradation, resulting in poor print quality, weak structural integrity, and decreased performance.

02

Print Consistency

- Inconsistent humidity levels can cause variations in material properties, leading to uneven prints and layer adhesion issues.

- Print defects like warping, delamination, and surface imperfections are often caused by uncontrolled humidity during the printing process.

03

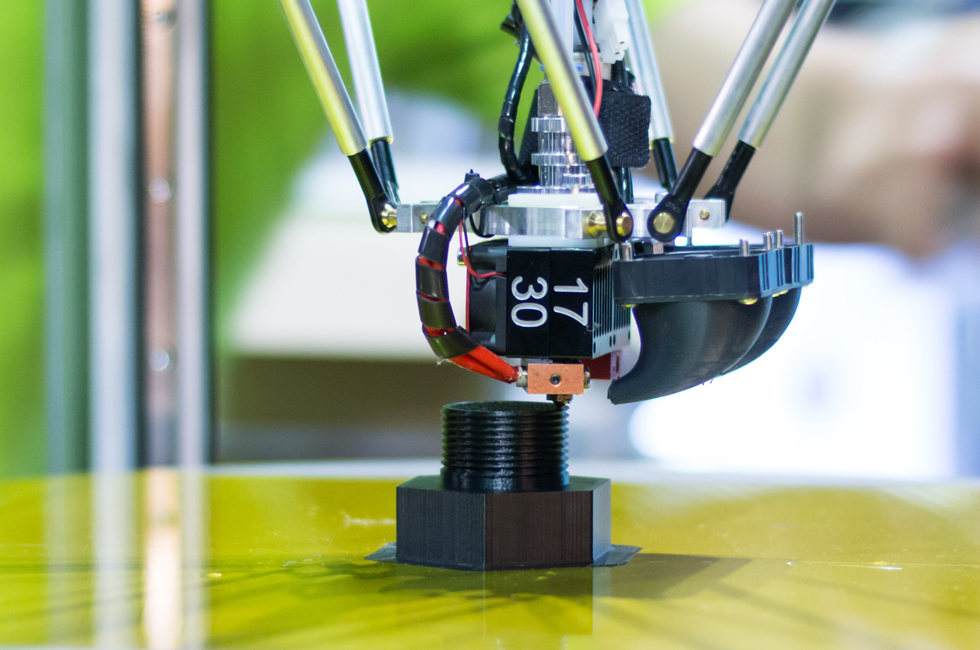

Equipment Performance

- 3D printers rely on precise temperature and humidity conditions to operate optimally.

- High humidity levels can affect the extrusion process, causing nozzle clogs and erratic filament flow, leading to print failures.

For 3D printing professionals and enthusiasts, achieving consistent and high-quality results is paramount. Humidity control plays a pivotal role in this endeavor, and Dr. Storage's innovative technology offers the perfect solution. By investing in Dr. Storage's system, you're not just safeguarding your 3D printing materials; you're ensuring that every print is a masterpiece of precision and reliability. Elevate your 3D printing game with the power of humidity control from Dr. Storage.